UltraKote UVSEAL - Single pack Polyurethane

UV-Stable Single Pack Polyurethane Clear Coating

Regular price

$100.00 - $200.00

Sale price

$100.00

Regular price

inc GST

Choose your option

Epimax 999WB - Two pack, water based, clear epoxy sealer

Two Part Economic Epoxy Concrete Sealer

Regular price

$100.00 - $1,480.00

Sale price

$100.00

Regular price

inc GST

Choose your option

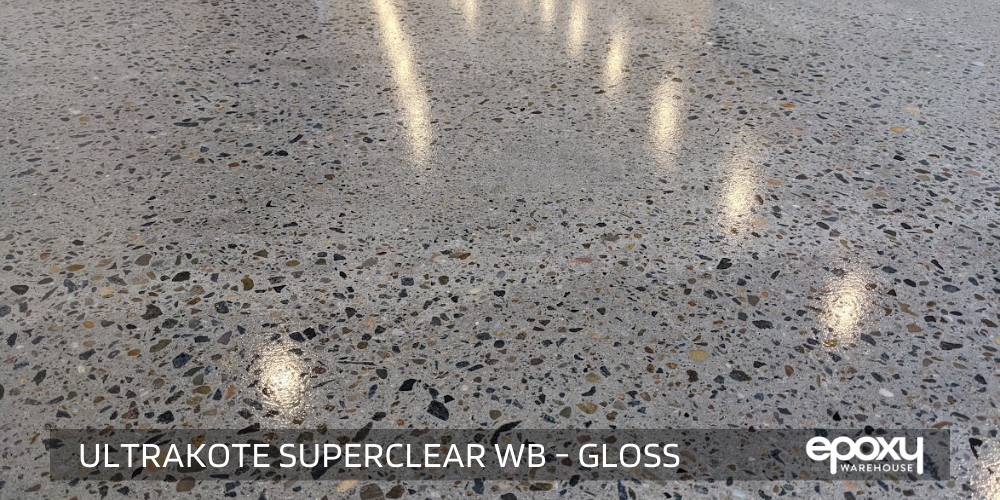

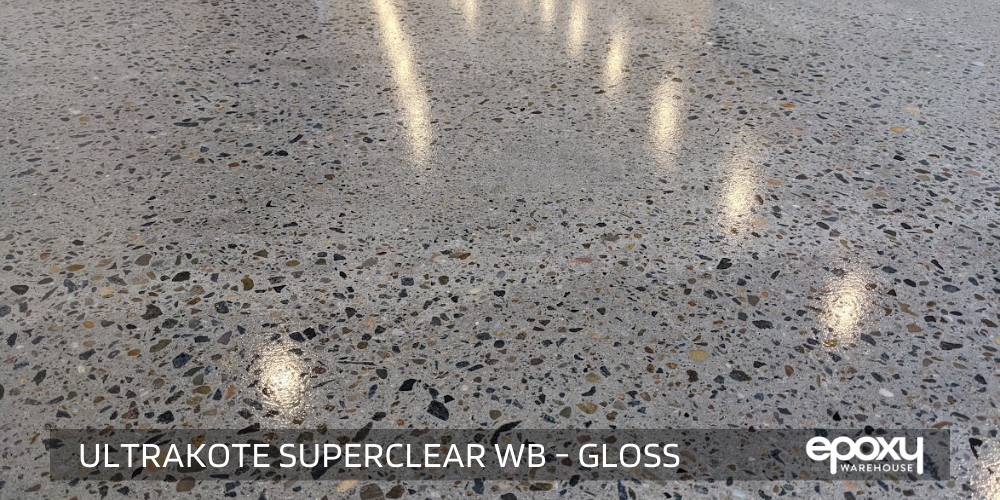

UltraKote SuperClear WB 5 litre kit

Two Pack Water-based Polyurethane Clear Protective Coat.

Available in Gloss and Matt

Available in Gloss and Matt

Regular price

$240.00

Sale price

$240.00

Regular price

inc GST

Choose your option

XPS Rockhard USA Epoxy - 3 Gallon Kit

Regular price

$412.50

Sale price

$412.50

Regular price

inc GST

Choose your option

Choose your option

Steps to achieving a successful Clear Floor Coating Solution

- Prepare the concrete thoroughly by diamond grinding with a course grit | Diamonds Info To achieve a successful floor coating system make sure your surface is free of dust, oil/grease, any loose particles or paint and moisture. | more info

- Polish the concrete using a higher grit diamond cup wheel Ensure the floor is level and polished consistently to avoid grinding marks or imperfections showing in the completed application.

- (OPTIONAL) Repair cracks and imperfections using two-pack epoxy fillers As this is a clear floor coating system, patching imperfections will be very noticable on the floor. It is completely up to the applicator's preference as most prefer the natural look of the cracks and feel that the imperfections are what make the floor perfect for them. Fill in all your cracks using a 2-pack epoxy filler, such as Sikadur 31 CFN. For larger cracks and spalls, use Sydney Industrial Coatings’ Epoxy Coving and Repair Kit. The patching mortar will need to be fully cured before it can be grinded or coated and this process usually takes a minimum of 6 – 8 hours.

- Apply the first coat to the floor and allow the coating to cure General curing time (at 20°C) is a minimum of 8 hours. This can vary further if solvent has been added to the coating. General curing time (at 20°C) is minimum 8 hours. It is always reccomended to back roll the product against the natural light to assist with achieving a more uniform finish. Wearing spike shoes to walk over the epoxy can help ensure the product is applied evenly, however you must apply safety practices and be cautious of injury.

- Return within 24 hours of applying the first coat to apply the second coat Using thinners in the final (or finish) coat is not recommended. If this step if not completed within 30 - 36 hours (depending on temperature) of applying the previous coat, the floor will need to be scratched using an 80 grit sand paper.

- (OPTIONAL) Return and apply another coat as per above If you are applying the system over porous concrete, a third coat may be required. If a third clear coating is required, repeat step 5.

- Antislip media can be added to the topcoat to achieve a higher slip rating

- Your floor will be trafficable after 24 hours and heavy items such as cars, boats or trailers shouldn’t be parked on the floor for 7 days after application of the final coat

FREQUENTLY ASKED QUESTION

What does a clear finish system/concrete sealer do?

The purpose of a clear finish system is to protect the appearance of concrete surfaces to seal and protect from moisture, stains and other damage.

What are the different types of seal coating systems?

There are three types of sealers: penetrating, topical and polyurethane.

Are epoxy sealers suitable for outdoor applications?

Some epoxy sealers are formulated specifically for outdoor use, providing UV resistance and protection against the elements. Understanding the limitations and recommended applications of epoxy sealers helps users make informed decisions based on their project requirements.