Description

Sika FerroGard 410 Patch CC is a zinc based discrete sacrificial anode placed in reinforced concrete structures which are corroding as a result of chloride ingress and / or carbonation.

Sika® FerroGard®-410 Patch CC discrete anodes are placed into sound carbonated or chloride contaminated concrete outside of any concrete repaired areas.

Once installed, the Sika® FerroGard®-410 Patch CC anodes will corrode preferentially to the surrounding reinforcement, offering protection against corrosion damage.

USES

- Corrosion control of zones within sound contaminated concrete.

- For reinforced concrete structures such as bridges, car parks, coastal structures, industrial structures and residential high-rise.

- Coastal reinforced concrete structures both in and above the tidal zone

CHARACTERISTICS AND ADVANTAGES

- Sika® FerroGard®-410 Patch CC anodes corrode preferentially to the surrounding reinforcement, offering protection from further corrosion damage.

- No long term maintenance costs

- Conforms to the latest EN 12696:2012 standard for impressed current cathodic protection, when designed appropriately

- Large charge capacity of up to 500 kC with option of sizes.*

- Rapid and targeted installation

- Performance can be monitored

- Pre-packaged embedding mortar

- No need to break-out large areas of sound contaminated concrete

- Lifetime of up to 20 years*

* Dependent on local conditions, including chloride concentration, concrete properties, humidity and temperature.

Colour

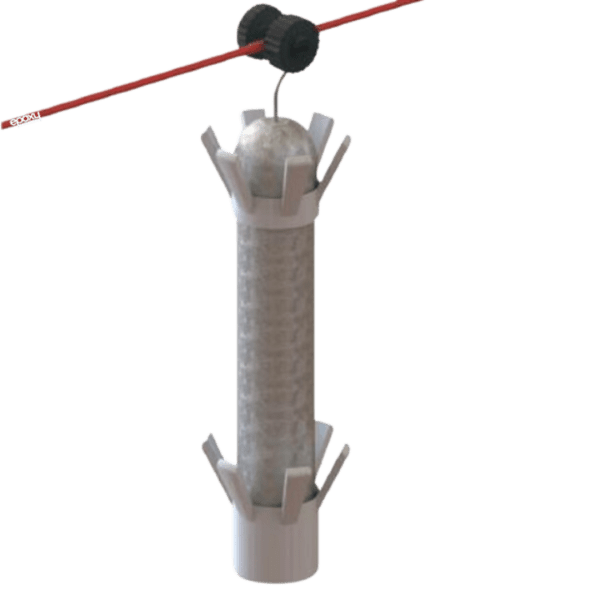

Cylindrical zinc core covered in an activated coating, separate white spacers and an integral titanium connecting wire.

PACKAGING

25 anodes per box, vacuum packed in 5 separate pouches

APPLICATION

Reference must be made to the Sika Method Statement: Corrosion Control using Discrete Galvanic Anodes Sika® FerroGard®-400s Patch CC for further details. This is summarised below:

Sika® FerroGard®-410 Patch CC anodes are installed following guidelines in EN 12696:2012 and CEN/TS 14038-1:2004.

The anodes are typically positioned at a density of 4–9 /m2 of surface concrete. Spacing between anodes: 280–600 mm.

Install into pre-drilled (30 mm diameter holes with a depth of ~80 mm) previously filled with Sika® FerroGard®-500 Crete embedding mortar to completely encapsulate the anode.

Electrically connect each anode to a titanium feeder wire which is connected to the reinforcement. This allows an option to deliver an electrical charge to the reinforcement at any point in the future should a change in environmental conditions demand greater protection of the reinforcement. In this situation, Sika® FerroGard®-410 Patch CC system conforms to the latest EN 12696:2012 standard for impressed current cathodic protection.

The Sika® FerroGard®-410 Patch CC anode installation can be monitored using half-cell potential surveys, current outputs and reinforcement corrosion rate measurements.

Sika® FerroGard-410 Patch CC Datasheets

Sika FerroGard 410 Patch CC – Sika’s Website

Reviews

There are no reviews yet.